Thermoset Moulding Services

Price 100 INR/ Piece

Thermoset Moulding Services Specification

- Surface Finish

- Smooth, Glossy or Matte as specified

- Capacity

- Small to Large Batch Production

- Type of Moulding

- Compression / Injection

- Minimum Order Quantity

- As per client requirement

- Tolerance

- Up to ±0.05 mm

- Delivery

- By road/air as applicable

- Color Options

- Black, White, Custom Colors

- Service Location

- Pan India

- Service Mode

- Offline

- Moulded Material

- Thermoset

- Material Thickness

- Customizable as per requirement

- Design Support

- Available

- Application

- Electrical, Automotive, Industrial Components

- Lead Time

- 2-4 Weeks

Thermoset Moulding Services Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3 Days

About Thermoset Moulding Services

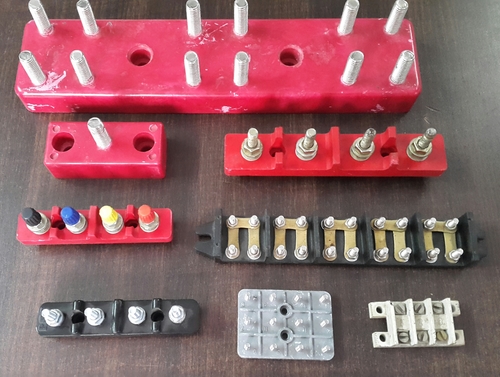

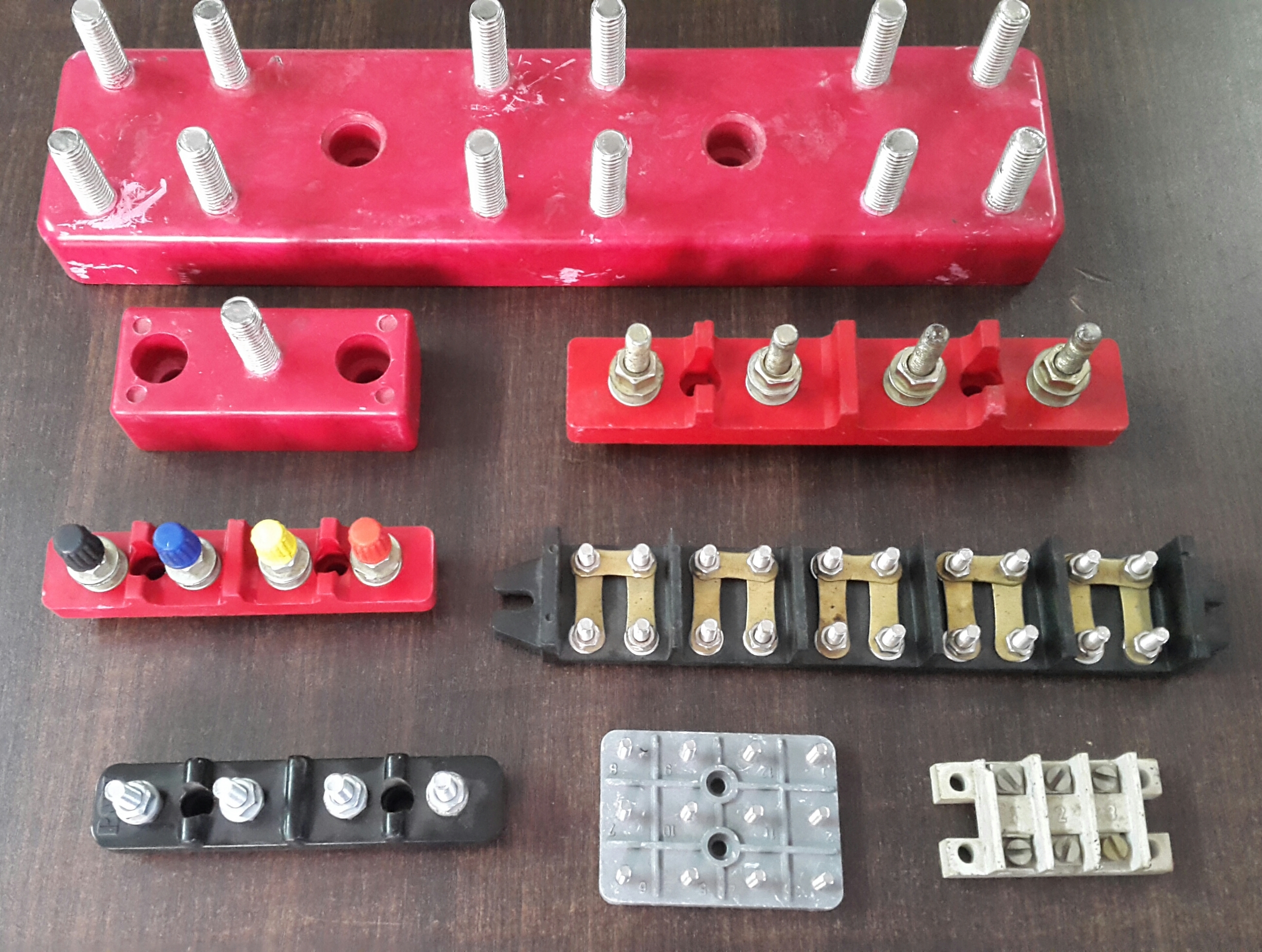

We have uniquely positioned ourselves as the dependable firm, occupied in providing a wide range of Thermoset Moulding Services. These services are rendered with the help of our professionals, who have vast experience and understanding of moulding work. We use excellent tools and innovative techniques. Also, the Thermoset Moulding Services offered by us are acclaimed for its reliability, complete satisfaction and cost effective. Our clients can avail these moulding services from us at reasonable costs within the committed time frame.

Catagory of Thermoset Moulding Services.

1. DMC Moulded Services.

2. SMC Moulded Services.

3. Backlite Moulded Services.

4. Rubber Moulded Services.

Technical Specification

| Contact Material | Brass |

| Brand | RMW |

| Usage/Application | Water Pump, Electrical Motor |

| Mounting Type | Panel Mounting |

| Voltage | 220/230 V |

| Pin Type | 4 Way, 6 Way, 8 Way, 12 Way |

| Current Rating | 16A |

Precision Engineering for High-Quality Components

With advanced moulding facilities and experienced technical support, we deliver thermoset parts tailored to stringent specifications. Exceptional accuracy within 0.05 mm tolerance ensures reliable functionality, making our services perfect for demanding electrical, automotive, and industrial components. Our skilled team guides you through design, prototyping, and production, ensuring efficiency throughout the process.

Customizable Solutions for Every Application

From surface finish to color and material thickness, every aspect is customizable to suit your projects needs. Whether you require a glossy, matte, or smooth finish, or even custom color matching, we offer flexibility and creativity. Batch sizes are tailored as per client demand, ensuring scalable production with no compromise on quality.

Pan-India Delivery and Efficient Turnaround

Our service is accessible nationwide, delivered through reliable road or air transport. Lead times range between two to four weeks, depending on project complexity and order requirements. Customers benefit from streamlined offline service, comprehensive support, and timely delivery, ensuring your components reach you exactly when needed.

FAQs of Thermoset Moulding Services:

Q: How does your thermoset moulding process ensure precise tolerances and surface finishes?

A: We utilize advanced compression and injection moulding equipment, combined with experienced operators and strict quality control, to achieve tight tolerances of up to 0.05 mm. Surface finisheswhether smooth, glossy, or matteare achieved through meticulous mould design and finishing techniques, as specified by client requirements.Q: What industries and applications are your thermoset moulded parts best suited for?

A: Our thermoset moulded components are ideal for electrical, automotive, and industrial applications requiring high heat resistance, electrical insulation, and durable surfaces. Typical uses include switchgear housings, automotive panels, industrial connectors, and more.Q: When can I expect delivery of my thermoset moulded order?

A: Lead times for our thermoset moulding services typically range from 2 to 4 weeks, depending on the batch size and complexity of your requirements. We coordinate closely with clients to meet project deadlines and arrange prompt delivery via road or air across India.Q: Where do you deliver your moulded products and what service modes are available?

A: We offer pan-India delivery, reaching clients in all major cities and industrial hubs. Our services are primarily offline, with personalized design support, consultation, and after-sales assistance at every stage of production and delivery.Q: What is the minimum order quantity and how scalable is your production capacity?

A: We are flexible with minimum order quantities, accommodating both small and large batch productions based on client needs. Our scalable production facilities enable us to handle varied order sizes without compromising on quality or lead times.Q: How does the design support process work for custom thermoset moulding projects?

A: Our design team collaborates with clients from the initial concept through prototyping and final production. We assist with material selection, part design, and optimization to ensure both manufacturability and functionality meet your specifications.Q: What are the main benefits of choosing your thermoset moulding services?

A: Clients benefit from excellent dimensional accuracy, customizable finishes and colors, rapid lead times, and comprehensive support throughout the project lifecycle. Our quality-driven approach ensures cost-effective and reliable solutions for diverse industrial needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry